Photo Courtesy: The Met Museum, Online

Screen-printing is a process where ink is forced through a mesh screen onto a surface. Making certain areas of the screen impervious to printing ink creates a stencil, which blocks the printing ink from passing through the screen. The ink that passes through forms the printed image.

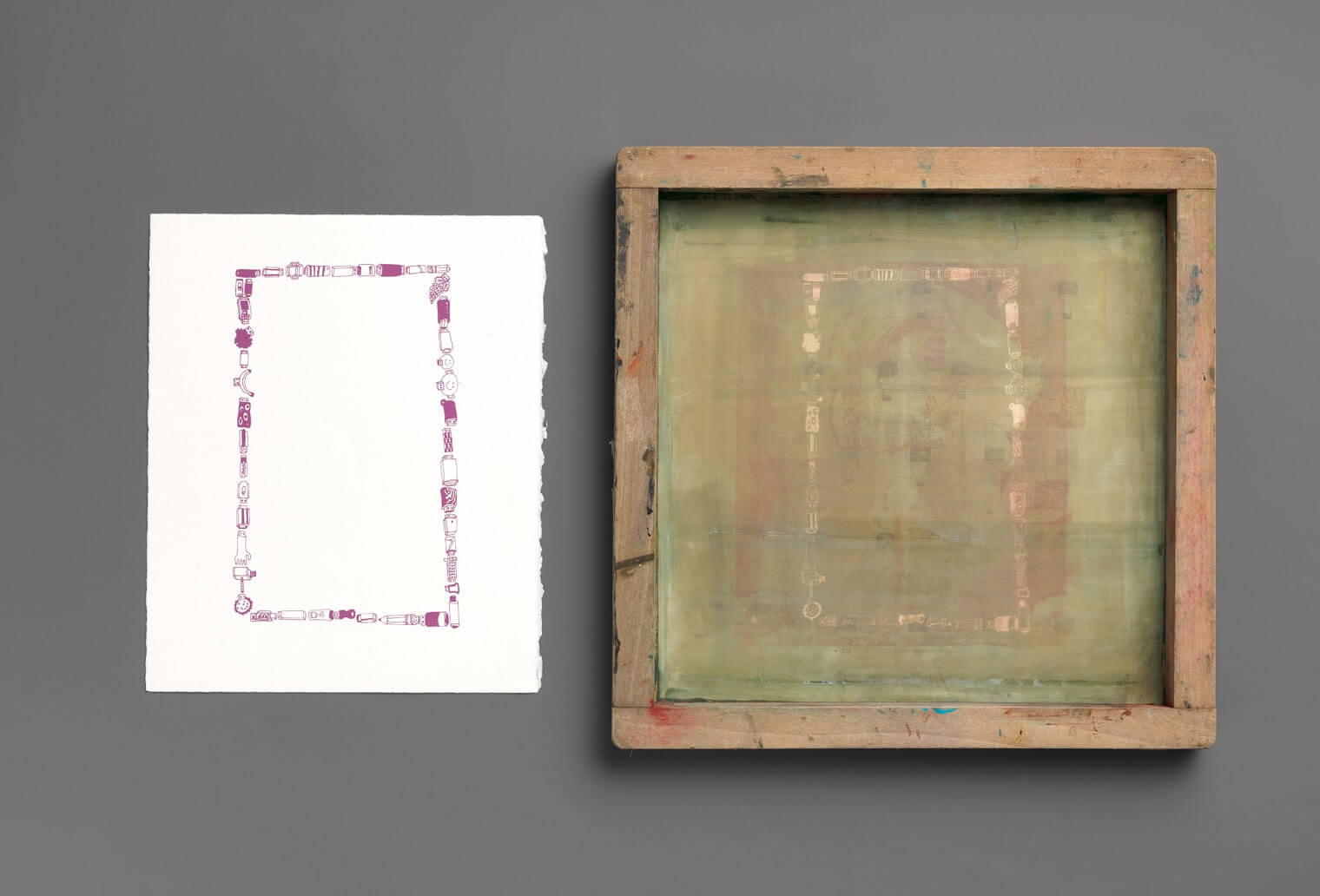

A printing screen consists of a fine mesh fabric that is tightly stretched and attached to a metal or wooden frame. Traditionally these screens were made of silk, but today they are most often made of synthetic materials such as terylene.

Stencils—which can be composed of a wide variety of materials, including fabric, greasy paint, or a design on a transparency—can be applied to the screen in different ways: placing them directly onto the surface of the screen, painting them onto the screen, or by transferring a design onto the screen using a photo-sensitive emulsion. The transfer of a design on transparency or Mylar film onto a photo-sensitive emulsion is the most common contemporary method to prepare a screen. Designs can be made by any or a combination of the following ways: hand-drawn with an opaque ink or printed onto the transparency, or cut out of rubylith, an ultraviolet-masking film.

To transfer the design from the transparency, the screen is first coated with a thin layer of photo-sensitive emulsion using a scoop coater, a metal trough that has a clean, even edge. After the emulsion dries, the design is placed against the screen. The screen is then placed in an exposure unit that emits ultraviolet (UV) light. When the exposure unit is on, the design blocks the UV light that hardens the emulsion around the image. The emulsion covered by the design remains soft and is then washed out of the screen, leaving the design on the screen.

Once the screen has been prepared, it is placed in hinges affixed to a board or screen-printing table, which has hinges at the top and holes in the surface that allow a vacuum to hold a sheet of paper in place during printing. A thick bead of ink is applied along the top of the inside of the screen and then pulled evenly across the image using a squeegee, an action known as “flooding the screen.” A sheet of paper is then placed under the screen, and with another pass of the squeegee the ink is pushed through those areas of the screen that are not blocked by the stencil. The resulting impression follows the direction of the matrix. If the composition requires more than one color, the printmaker must repeat the process using a different stencil for each color. To keep the colors of the composition aligned, the printmaker must take precautionary measures to ensure the proper registration of the sheet of paper and the screen.